The city of Garland’s Make Your Mark campaign was officially set in motion less than a year ago, but several Garland businesses and untold numbers of their employees made their mark in the 1960s by being part of the design and manufacturing of numerous items associated with the Apollo 11 space mission. Yes. The one where Neil Armstrong and Buzz Aldrin walked on the moon.

After receiving a letter from the American Association of State and Local History suggesting that local museums put together a summer exhibit about the 50th anniversary of the moon landing, Kim Nurmi, Heritage Crossing coordinator, decided to see what she could find.

“As I started looking into it, it wasn’t just that Garland has a couple of space industries present day. It was that Garland had been part of the space industry for a huge part of its history,” she said. “We had five different, independent corporations that were actually involved in some way with the Apollo 11 mission.”

Nurmi was surprised to learn that so few people were aware of Garland’s involvement in such an important historic event that should be a source of community pride.

Below are the companies with brief explanations of their contributions:

VARO, Inc.

- Semiconductor Division, Garland, furnished bridge rectifiers used in ground support equipment.

- Developed alternator for Lunar Excursion Module used during flight of LEM

from Apollo spacecraft to the moon’s surface.

from Apollo spacecraft to the moon’s surface.

INTERCONTINENTAL Manufacturing Co. (IMCO)

- Produced items that were part of the Apollo-Saturn V system – motor cases and closures.

- Built inter-stage assemblies to keep the motor case in position during take-off. In case of an abort, the 33,000-pound thrust provided by IMCO case and closure would guide the command module toward the ocean for safe landing.

SPACE Corp.

- Supplied launch support products used in tests before space vehicle launch.

- Supplied camera and engine support equipment used to monitor operations inside spacecraft.

- Provided launch equipment including hold-down arms which restrained motion of the Saturn vehicle until sufficient thrust was attained to allow liftoff.

CONTROL & COMPUTING DEVICE Co.

- Built console which tested and calibrated instruments used in evaluating rock samples Apollo astronauts brought back. Instruments utilized infrared technique.

LTV ELECTROSYSTEMS, Inc.

- Designed, fabricated and installed automated display board at NASA’s Manned Spacecraft Center in Houston. Board displays exact position of orbiting space vehicle on large map of earth.

“Think about this. In every movie about space and in every historic photo you see the big bank of monitors in mission control,” Nurmi said. “And those were designed and manufactured right here in Garland and LTV employees took them to Houston and installed them.”

NASA thought of a unique way to instill pride and the desire to provide quality workmanship in employees involved in the mission and Garland was proud to be a part of that as well.

In early 1969, NASA assembled a mobile exhibit called the Craftsman Ship. It housed examples of items being manufactured around the country for the space mission and was driven to cities where parts were being made so that employees could see the significance of their work.

This added reality to the employees’ mission of ensuring the security of the astronauts’ lives and the success of the Apollo mission because they could visualize the parts that must fit perfectly together.

Garland’s involvement with NASA has continued since the Apollo 11 mission through GEOTECH, IMCO and MICROPAC Industries. Each has made significant contributions to the space program as well as other technology-related applications.

GEOTECH designed and built a lunar seismometer system that studies the moon mantel by sound wave probes. They built the small Active Detonation System, a subsystem of the Active Seismic Experiment of the Apollo Lunar Surface Experiments Package.

IMCO manufactured Castor 4 solid-fuel rocket stages and boosters for some Delta, Delta II, Atlas IIAS and Athena launch vehicles and designed and manufactured a yoke to balance rockets when raised for take-off.

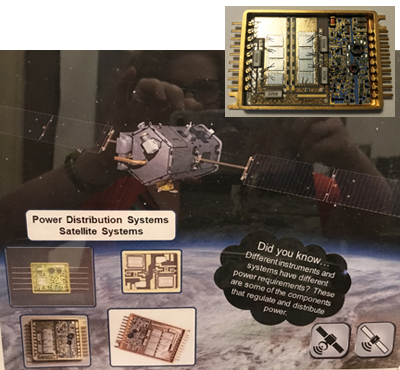

MICROPAC’s satellite programs are used by NASA, the military and commercial satellites. Other applications include star trackers, retro rocket firing mechanisms, camera systems, power distribution systems, motor controllers and thermostats.

MICROPAC has provided a distinction for Garland that few cities share. Because of their contribution to the design and manufacturing of parts for the Mars Rover, Garland can brag that something made here now sits on Mars.

Mark King, MICROPAC’s CEO and president, was instrumental in the creation of the Landmark Museum space exhibit by providing extensive information and exhibit items. The manufacturing company, under King’s direction, is a valuable community partner.

There are two chances left to view the exhibit — Saturday, Aug. 17 and Saturday, Aug. 24, 10 a.m. – 2 p.m. The Landmark Museum is at Heritage Crossing, 393 North Sixth Street in downtown Garland. 972-205-2996.